A Beginner's Guide to Metal Roofing Materials

christine • August 10, 2020

Get A Free Quote Today!

Get A Free Quote Today!

Get A Free Quote Today!

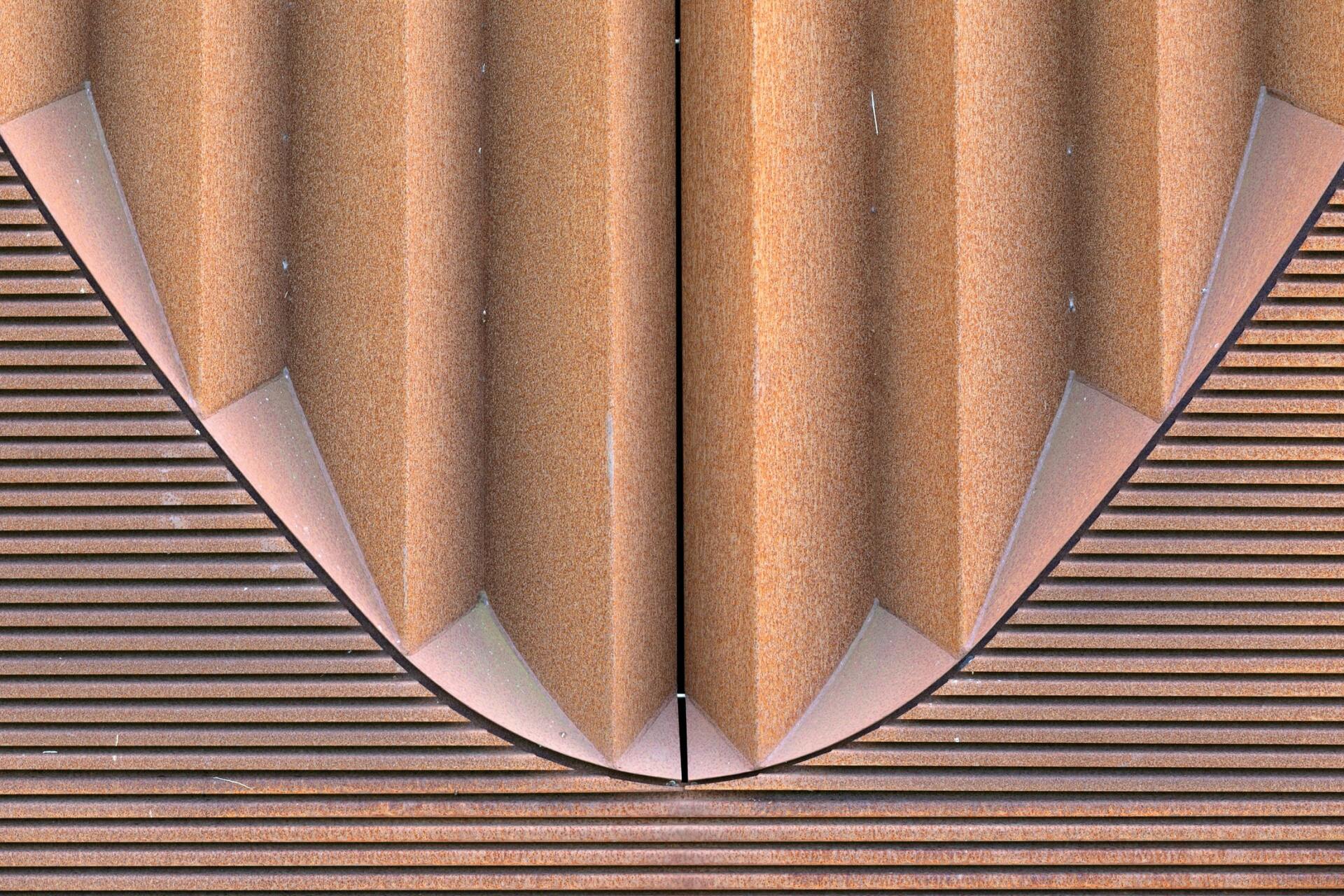

Panels

It all starts with your panels. These come in long sheets with ribs, and it's the raised portions of the panel that provide the rigidity you need and strength for your roof. Panels can be installed in multiple rows, but most of the time they run in a continuous line from the peak of the roof all the way down to the gutter.

The Importance of Rolling on Site

When working with panels, the ideal roofing material company to work with is one that can roll your panels on site. This allows you to make last-minute changes with ease, and it's why we offer this service at Hill Country Metal Roofing Supply. On-site rolling also eliminates the cost of shipping heavy panels in sections, much of which you will need to trim off. There's also no need to worry about late deliveries or trying to work your project into someone else's shipping time frames.

When you have your panels rolled directly on site, you also avoid having to hire or buy expensive equipment for unloading materials. Instead, you can get everything stacked in the right area with all accessories and trim components in the same place. Finally, on-site rolling allows you to significantly reduce waste. Every panel can be custom-fabricated to the right size and shape, meaning there are no waste bits that have to be trimmed.

Panel Colors

Metal panels come in all colors, but the most environmentally conscious roofs are white or a similar light color. By choosing a white metal panel, you can reduce the energy use of a property by anywhere from 18% to 26%.

Types of Fastener Systems

Fastener systems can be through fastener or standing seam variety. These terms refer to how the panels are installed on the roof.

Through Fastener

Through fastener metal panels are quick to install. They use long-lasting, strong screws that are painted to match the metal panels and come equipped with a neoprene rubber seal and cap to protect the seal from the UV rays of the sun.

The Problem With Through Fastener Systems

There's a serious downside to this type of metal roof, and that's the increased risk of leakage and corrosion. Any time you have a hole, even when the screws are well painted and capped, there's a bigger risk of leaks. That's why through fastener metal roofing systems typically can't offer the extended warranty that you'll get with standing seam or hidden fastener metal roofing materials. A through fastener roof will have hundreds or even thousands of fasteners and rubber grommets, each of which penetrates the surface and is subject to installation error.

When these fasteners are installed, it's crucially important to tighten each to exactly the right torque and no further. Too tight and the screws will fail. Too loose, and they will leak or fail in high winds.

Standing Seam Fasteners

The standing seam, or concealed fastener, is the ultimate rust-proof system that needs the least maintenance and lasts the longest. At Hill Country Metal Roofing Supply, we offer the SnapLoc single and double-loc standing seam panels with a concealed fastener system because it's simply the most reliable material for your roof. When you use a standing seam system, you get the full warranty on the entire system, and the lack of exposed fasteners means you have much less possibility of any corrosion or leakage.

How It Works

Standing seam panels fasten using hidden clips that snap-lock together. These roofs are attached to the roof deck with clips or with a flange. Fasteners go through clips and into the roof deck, but no fasteners pierce your metal panels.

Roof Areas and Flashing

As you consider flashing, one of the key metal roofing materials, it's important to know the areas of the roof so you understand where things like flashing and trim components go. The main areas of a roof are:

Ridge or top cap: where the upper ends of two sections meet

Eave or drip edge: the lower end of a roof section where it meets a wall

Valley: the lower ends of two sections that meet diagonally

Hip: the upper ends of two roof sections that meet diagonally

Gable or Rake: the side of a roof section that meets a wall or fascia

Sidewall: a side section that goes up a wall

Endwall: an upper section that goes up a wall

Low wall: the lower end of a roof that goes up a skylight or chimney

Flying gable or flared gable: an angled side of the roof where it terminates and goes down the wall

Flashing

The reason it's important to know the names of the different areas of your roof is that the flashing suitable for that section will usually bear the same or a similar name, and flashing has to be shaped in just the right way to accommodate the area of the roof it's going to cover.

Flashing is usually made of aluminum or galvanized steel, and it goes over the joints of the roof where one section meets another. It's also used around any penetration point. Almost every roof has at least one penetration point; typically the bathroom vent pipe. Most have several types of penetration, including:

Exhaust vents

Conduits

Turbine vents

Chimneys

Skylights

Satellite dishes

Solar panels

Cupolas

Steeples

Walking platforms

Mounted signs

HVAC curbs

Each of these penetrations is another place where water can get through, so flashing is crucially important to protect the roof. Flashing is fairly simple. When installed the right way, it uses nothing more than gravity to wick water away and off the roof.

Doing It Right

Flashing is usually the most technically difficult aspect of any roof, and it's important to be able to roll your metal panels to just the right shape for protecting an individual area of penetration. Flashing is more prone to failure than the metal panels themselves, so it's especially important to use the right material for the job and install the flashing carefully for the best results and greatest protection for your structure.

Drip Metal

This is a special type of flashing for making a drip edge. The drip edge is applied along the roof's edge to give water a way to filter off the roof. This type of flashing has to be non-staining and non-corroding. Drop edges not only move water and assist the gutter system but also deter insects and pests from getting between the fascia board and the roof deck.

Underlayment

Any underlayment is a thin layer between any two other layers. In this case, it's a layer of waterproof material that goes directly onto the roof deck for added protection against the elements.

Butyl Tape and Sealants

These are crucial metal roofing materials. Butyl tape is used to seal metal panels on the sides and ends. It also provides a final layer of protection for areas of penetration and optimal sealing for harsh environments.

Butyl tape is unique in that it can adhere to nearly any surface and is able to withstand extremes of temperatures that other tapes cannot endure without melting or becoming brittle and failing. Butyl itself is a specialized rubber developed to retain tackiness and perform much better at both higher and lower temps than ordinary rubber tape.

This tape is impermeable to air and thoroughly waterproof, making it ideal for seaming and flashing on the roof. It's also frequently used in repairing leaks. Waterproof roof caulk or other types of liquid sealants are also used to completely seal a seam after it's been covered with butyl tape.

Chimney Caps

A chimney cap keeps certain things out and other things in. It stops water, moisture, animals, and birds from getting in the chimney. At the same time, it stops UV rays from damaging the top row of brick on the chimney. The chimney cap also stops sparks and embers from escaping and allows smoke to property draft. Chimney caps can and should be custom made so they fit the unique chimney they're meant to protect while enhancing the look of the home and roof.

Get All Your Metal Roofing Supplies

A lot of supplies going into making a good roof, and when you need the best protection for your investment, call 512-676-5838 or visit Hill Country Metal Roofing Supply. We can roll your panels at your site and have everything you need at your fingertips without delays or shipping costs, ensuring your roofing project goes forward on time and within budget.

Get A Free Quote Today!

The Importance of Rolling on Site

If you're considering a metal roof, you probably know that metal offers a significant improvement over older materials used for roofing projects. In this beginner's guide to metal roofing materials, we'll go everything you need to know about the materials that make it all happen.

Panels

It all starts with your panels. These come in long sheets with ribs, and it's the raised portions of the panel that provide the rigidity you need and strength for your roof. Panels can be installed in multiple rows, but most of the time they run in a continuous line from the peak of the roof all the way down to the gutter.

The Importance of Rolling on Site

When working with panels, the ideal roofing material company to work with is one that can roll your panels on site. This allows you to make last-minute changes with ease, and it's why we offer this service at Hill Country Metal Roofing Supply. On-site rolling also eliminates the cost of shipping heavy panels in sections, much of which you will need to trim off. There's also no need to worry about late deliveries or trying to work your project into someone else's shipping time frames.

When you have your panels rolled directly on site, you also avoid having to hire or buy expensive equipment for unloading materials. Instead, you can get everything stacked in the right area with all accessories and trim components in the same place. Finally, on-site rolling allows you to significantly reduce waste. Every panel can be custom-fabricated to the right size and shape, meaning there are no waste bits that have to be trimmed.

Panel Colors

Metal panels come in all colors, but the most environmentally conscious roofs are white or a similar light color. By choosing a white metal panel, you can reduce the energy use of a property by anywhere from 18% to 26%.

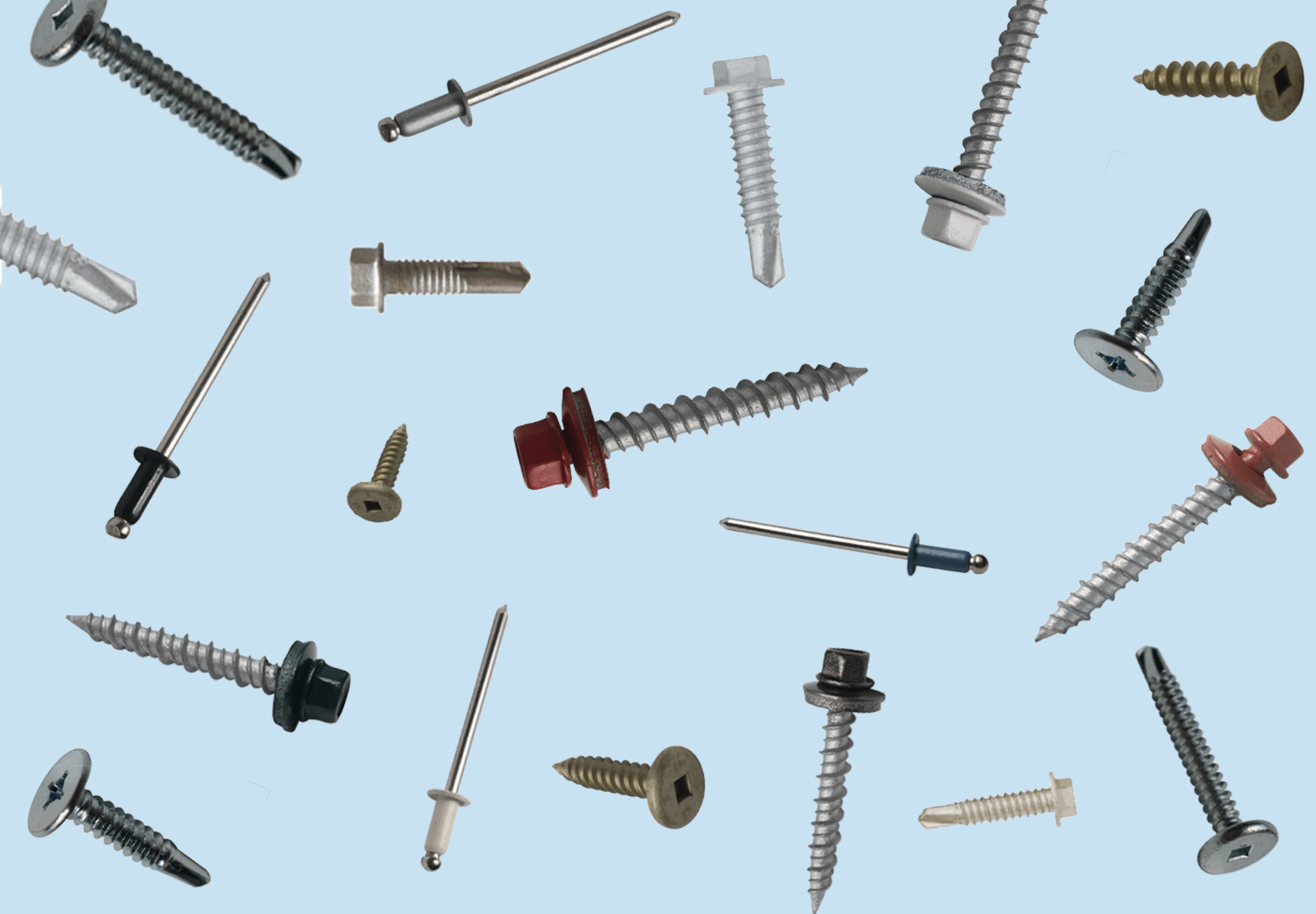

Types of Fastener Systems

Fastener systems can be through fastener or standing seam variety. These terms refer to how the panels are installed on the roof.

Through Fastener

Through fastener metal panels are quick to install. They use long-lasting, strong screws that are painted to match the metal panels and come equipped with a neoprene rubber seal and cap to protect the seal from the UV rays of the sun.

The Problem With Through Fastener Systems

There's a serious downside to this type of metal roof, and that's the increased risk of leakage and corrosion. Any time you have a hole, even when the screws are well painted and capped, there's a bigger risk of leaks. That's why through fastener metal roofing systems typically can't offer the extended warranty that you'll get with standing seam or hidden fastener metal roofing materials. A through fastener roof will have hundreds or even thousands of fasteners and rubber grommets, each of which penetrates the surface and is subject to installation error.

When these fasteners are installed, it's crucially important to tighten each to exactly the right torque and no further. Too tight and the screws will fail. Too loose, and they will leak or fail in high winds.

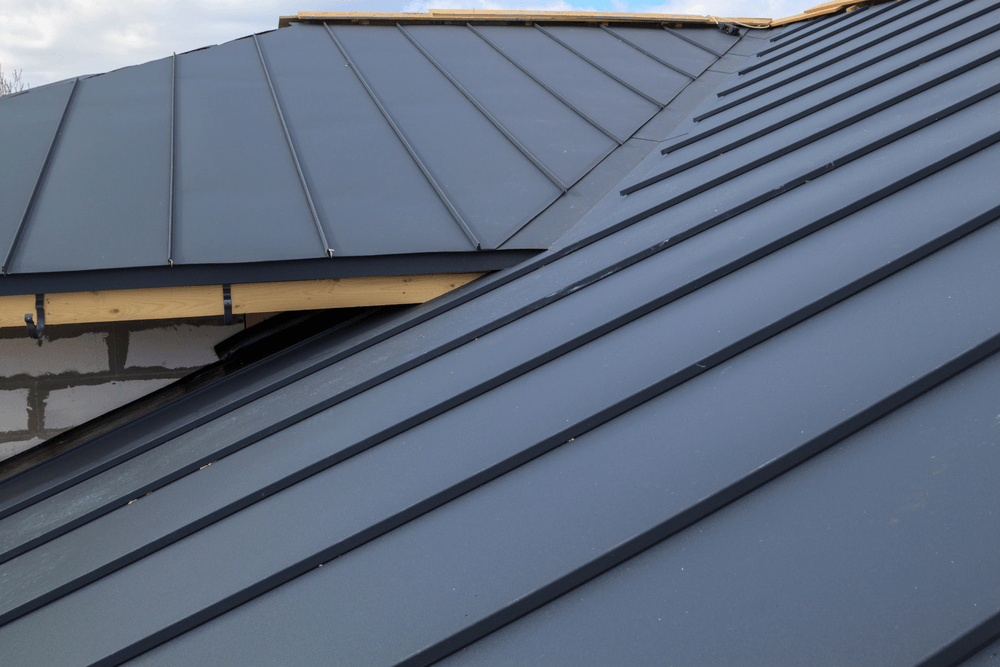

Standing Seam Fasteners

The standing seam, or concealed fastener, is the ultimate rust-proof system that needs the least maintenance and lasts the longest. At Hill Country Metal Roofing Supply, we offer the SnapLoc single and double-loc standing seam panels with a concealed fastener system because it's simply the most reliable material for your roof. When you use a standing seam system, you get the full warranty on the entire system, and the lack of exposed fasteners means you have much less possibility of any corrosion or leakage.

How It Works

Standing seam panels fasten using hidden clips that snap-lock together. These roofs are attached to the roof deck with clips or with a flange. Fasteners go through clips and into the roof deck, but no fasteners pierce your metal panels.

Roof Areas and Flashing

As you consider flashing, one of the key metal roofing materials, it's important to know the areas of the roof so you understand where things like flashing and trim components go. The main areas of a roof are:

Ridge or top cap: where the upper ends of two sections meet

Eave or drip edge: the lower end of a roof section where it meets a wall

Valley: the lower ends of two sections that meet diagonally

Hip: the upper ends of two roof sections that meet diagonally

Gable or Rake: the side of a roof section that meets a wall or fascia

Sidewall: a side section that goes up a wall

Endwall: an upper section that goes up a wall

Transition or pitch break: the lower end of a steep section where it transitions to the upper end of a more

shallow section

Gambrel: the lower end of a shallow sloped roof where it meets the upper end of a steeper slowed sectionLow wall: the lower end of a roof that goes up a skylight or chimney

Flying gable or flared gable: an angled side of the roof where it terminates and goes down the wall

Flashing

The reason it's important to know the names of the different areas of your roof is that the flashing suitable for that section will usually bear the same or a similar name, and flashing has to be shaped in just the right way to accommodate the area of the roof it's going to cover.

Flashing is usually made of aluminum or galvanized steel, and it goes over the joints of the roof where one section meets another. It's also used around any penetration point. Almost every roof has at least one penetration point; typically the bathroom vent pipe. Most have several types of penetration, including:

Exhaust vents

Conduits

Turbine vents

Chimneys

Skylights

Satellite dishes

Solar panels

Cupolas

Steeples

Walking platforms

Mounted signs

HVAC curbs

Each of these penetrations is another place where water can get through, so flashing is crucially important to protect the roof. Flashing is fairly simple. When installed the right way, it uses nothing more than gravity to wick water away and off the roof.

Doing It Right

Flashing is usually the most technically difficult aspect of any roof, and it's important to be able to roll your metal panels to just the right shape for protecting an individual area of penetration. Flashing is more prone to failure than the metal panels themselves, so it's especially important to use the right material for the job and install the flashing carefully for the best results and greatest protection for your structure.

Drip Metal

This is a special type of flashing for making a drip edge. The drip edge is applied along the roof's edge to give water a way to filter off the roof. This type of flashing has to be non-staining and non-corroding. Drop edges not only move water and assist the gutter system but also deter insects and pests from getting between the fascia board and the roof deck.

Underlayment

Any underlayment is a thin layer between any two other layers. In this case, it's a layer of waterproof material that goes directly onto the roof deck for added protection against the elements.

Butyl Tape and Sealants

These are crucial metal roofing materials. Butyl tape is used to seal metal panels on the sides and ends. It also provides a final layer of protection for areas of penetration and optimal sealing for harsh environments.

Butyl tape is unique in that it can adhere to nearly any surface and is able to withstand extremes of temperatures that other tapes cannot endure without melting or becoming brittle and failing. Butyl itself is a specialized rubber developed to retain tackiness and perform much better at both higher and lower temps than ordinary rubber tape.

This tape is impermeable to air and thoroughly waterproof, making it ideal for seaming and flashing on the roof. It's also frequently used in repairing leaks. Waterproof roof caulk or other types of liquid sealants are also used to completely seal a seam after it's been covered with butyl tape.

Chimney Caps

A chimney cap keeps certain things out and other things in. It stops water, moisture, animals, and birds from getting in the chimney. At the same time, it stops UV rays from damaging the top row of brick on the chimney. The chimney cap also stops sparks and embers from escaping and allows smoke to property draft. Chimney caps can and should be custom made so they fit the unique chimney they're meant to protect while enhancing the look of the home and roof.

Get All Your Metal Roofing Supplies

A lot of supplies going into making a good roof, and when you need the best protection for your investment, call 512-676-5838 or visit Hill Country Metal Roofing Supply. We can roll your panels at your site and have everything you need at your fingertips without delays or shipping costs, ensuring your roofing project goes forward on time and within budget.

Choosing to install a metal roof is an excellent decision for numerous reasons, including the fact that it will last much longer than a traditional roof, is more energy-efficient, and is better for the environment. However, there are some accessories that are highly recommended for your metal roof that will help make it more effective. These nine metal roof accessories will not only greatly enhance your roof's effectiveness, but will also increase its durability as well.

How heavy is a metal roof? You might be surprised to learn that it is one of the lightest options. Metal roofs are lighter than asphalt shingles, clay & concrete tiles. The weight of 26-gauge metal roofing is approximately just under one pound per square foot. The weight of 24-gauge metal roofing is about 1.15 pounds. The lower the gauge of the metal, the thicker and heavier the material will be.