(512) 676-5838

Blog Layout

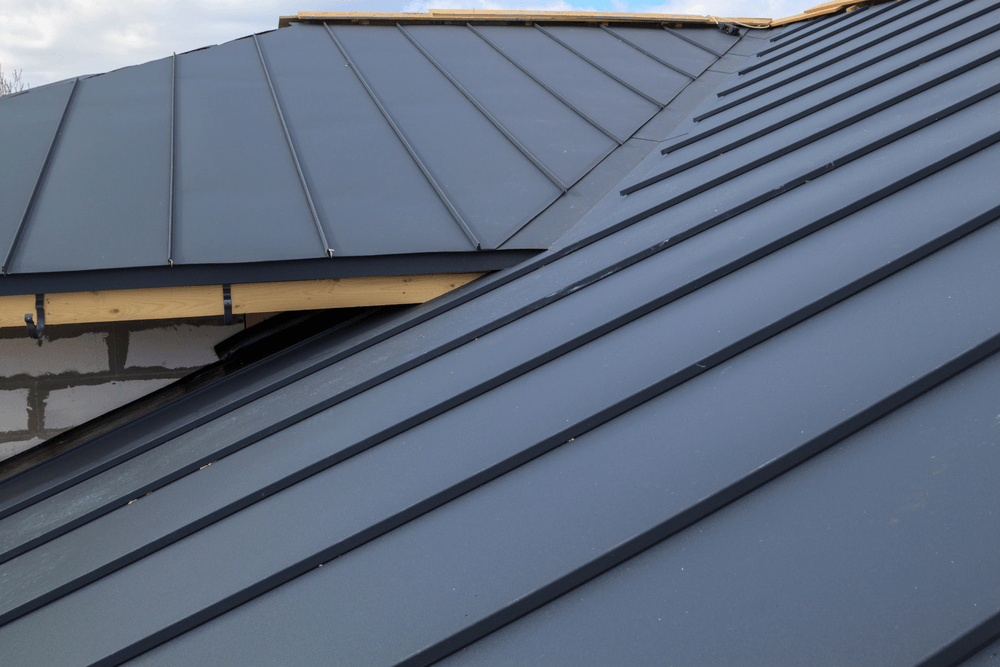

11 Metal Roof Accessories for Your Roofing Project

christine • April 20, 2020

Get A Free Quote Today!

Get A Free Quote Today!

Get A Free Quote Today!

11 Metal Roof Accessories for Your Roofing Project

Before you start your roofing project, make sure you have all the metal roof accessories you need. With all the right accessories in hand from the beginning, you won't have to worry about delays or budget overruns. Yet if changes do come to the project, working with a quality supplier means easy access to whatever accessories you need whenever you need them.

Drip Metal

Roof edges get the most moisture, especially if you have an irregularly shaped or very steep roof. Drip edge flashing metal directs the water where you want it to go, like into a gutter, and extends the longevity of your roof. Your drip metal flashing should be custom-made to match the size and shapes you need so you can install it at any angle and to any measurement.

Coping

The most vulnerable part of your walls are the horizontal surfaces at the top. If water is going to make its way in, it will be through this point. A properly fitted coping with a continuous edge strip can be used alone, or in combination with other materials, to protect the walls.

To figure the size of coping you'll need, be sure to note the weight of the material you want to use, the angle of the gutter sides, and the width of the gutter bottom. Once again, getting precisely the size and shape you need is crucial to keeping a project running smoothly.

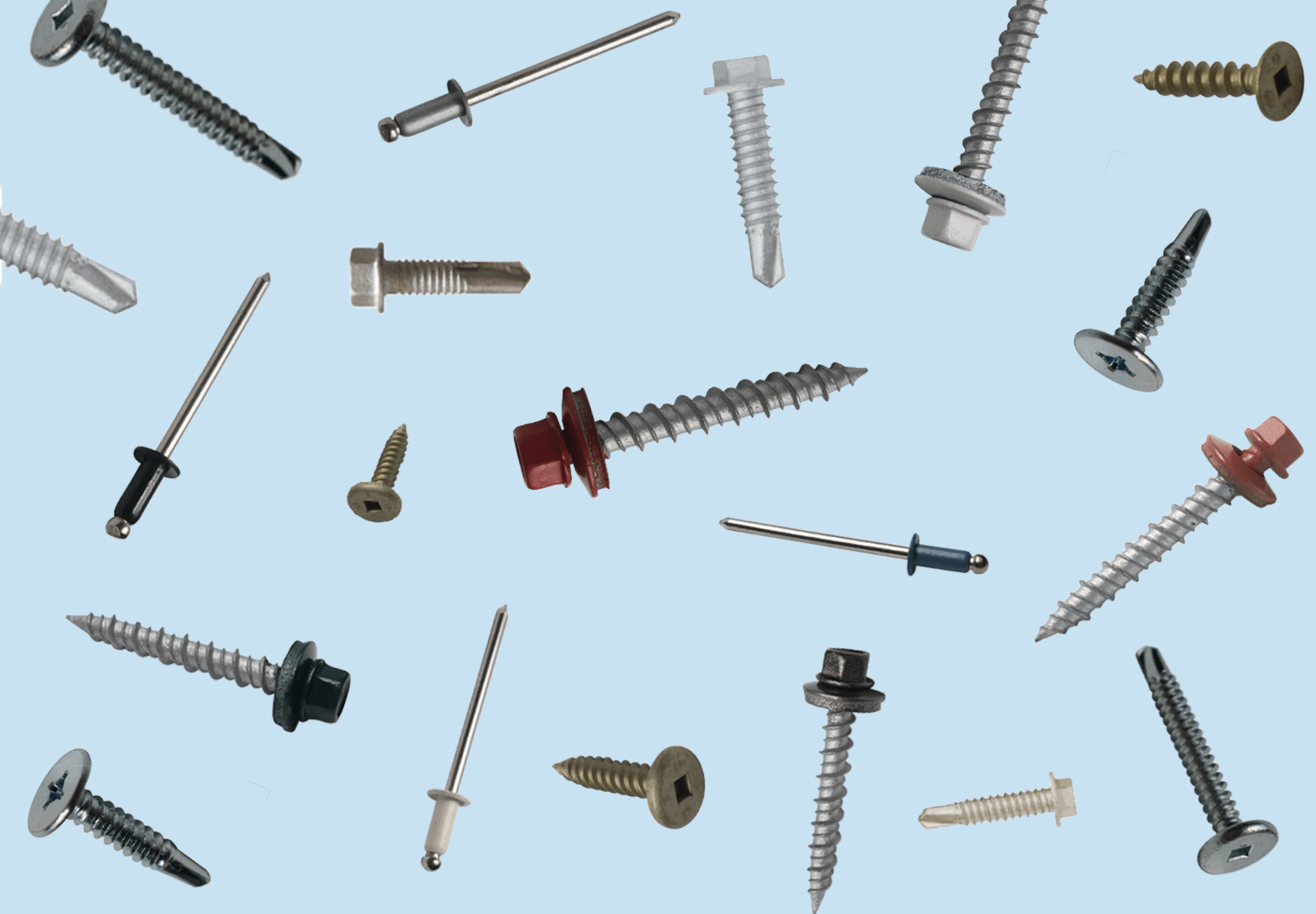

Metal Roofing Screws

To ensure a solid roof, you need the right screws, with heads that won't rust and micro-bits for quick penetration. The final choice of screw will depend on whether your substrate is concrete, metal, or wood and whether the screw needs to go through insulation. Uplight requirements should also be taken into consideration, but the two most important issues are the length and screw material.

The material will determine longevity and strength. Getting the right length of screw means the threads will properly attach to the substrate. When you consider screws, ask your supplier about the pullout loads to ensure you're getting the strength you need.

Gutters

Your roof isn't finished without gutters, but putting in guttering for metal roofs is a bit different from the way it's done on roofs made of traditional materials. In the first place, it's important to install your guttering a bit higher when joining it to a metal roof to be sure it catches the rain. It's also important to install a strong leaf guard.

In most cases, using a gutter system with brackets that attach to the fascia is your best choice. Attach the guttering through the fascia and into the rafter tails, and consider using six-inch rather than five-inch gutters for the best performance.

Underlayments

Roofing underlayments keep the roof deck dry before and throughout your roofing project. Once the roof is on, the underlayment provides a secondary line of protection against water and weather if the roof should fail at any point. Traditional roofing makes do with 30-pound felt paper underlayment, but for metal roofing, synthetic underlayments may provide superior performance because they are more tolerant of UV radiation and heat.

Synthetic underlayment can be up to 30 degrees cooler than paper while still ensuring that any water that gets past the metal roofing doesn't pass into the interior walls or any attic spaces. Look for wrinkle-free synthetic underlayment with anti-slip coatings. For some situations, paper might be the best choice, so talk to your underlayment supplier about the best underlayment for your particular project.

Custom Crickets

Wherever your roof is penetrated, you have a weak point. The joints between the roof and the chimney, or the roof and a skylight, are the most likely areas for leaking to begin. Joints must be flashed well, and you do that best with custom-made crickets that fit your project needs.

Look for a provider who can get you crickets built to any profile, size, or angle you need, so there's no delay to your project.

Chimney Caps

If your roof has a chimney, you want a custom-made chimney cap that matches the rest of your metal roof. These caps are essential for safe chimney functioning. They keep out birds, raccoons, and squirrels, protect your chimney itself from rain and leaves, and stop sparks from flying out. To top it all off, a well-made chimney cap simply looks good and adds to the aesthetic value of a roof.

Chimney caps can be made flat or peaked and made to fit any type of chimney without interfering with any convection cooling features (if your chimney is air-cooled).

Metal Trim and Flashing

Your trim and flashing are essential to keep water from getting through a joint. They are also key to your weather-resistant barrier system. The trim and flashing bring the metal panels together and, in conjunction with butyl tape, sealants, or other closures, provide a safe, watertight connection. Flashing and trim should be custom-cut to match your roofing project requirements.

Choosing Trim

The trim brings your roof together aesthetically, but it also protects and seals. You might put trim on the eaves primarily for decoration, but in other areas, the trim is far more essential. Rake trim or gable trim runs along the edge of your roof line, where the roof panel meets the end-wall panels: a key area that must be protected.

Transition trim, also known as sidewall and end-wall trim, is also important anywhere the roof meets the wall to seal any gaps in these abutting areas. Ridge caps protect the seam where two roof caps meet. Valley flashing is key anywhere the roof meets and forms a valley, to prevent water from getting under a panel.

Sealants and Caulking

Sealants and caulking are key to the life of your roof and the structure it protects. They fill in gaps and cracks and act as a barrier against anything you don't want getting through the roof, from water and dust to gas, noise, and air. Though these are some of the cheapest metal roof accessories, they are absolutely crucial to the project, and it's important to have plenty on hand.

Caulks

These are used anywhere you need sealant or filling, but where don't expect the metal in that area to expand or contract. Caulks are also used to prepare for painting. The key thing to know is that caulk is not flexible, so use it wisely. For metal roof projects, caulking usually goes on the interior gaps between drywall, around windows or trim, and on casework before painting.

Butyl Tape

This is a non-curing compound sealant that stays flexible even after exposure to the elements over time. Good butyl tape can last for 25 years or more and is compatible with all types of painted metal. Best of all, you can apply the tape at temperatures anywhere from -5 F to 120 F, and it will still provide good service at -40F and up to 200 F.

Sealants

Sealants function much like caulk but are used when you expect a lot of expansion or movement. The polymers in sealant allow it to flex, so it works well in places where two metal substrates meet, and you must have a watertight barrier. These can go on standing seams, metal roof ends, curbs, roof to wall transition points, boots, and more. Silicone sealants are popular and adhere very well, but they can't normally be painted.

Polyurethane sealant moves exceptionally well in joints and offers good adhesion for all materials except glass, though not as good as silicone. There are also butyl sealants, hybrid sealants, and many other choices, so talk with your metal roofing accessories supplier to learn more about what's right for your project.

Boots

Roof boots go into the flashing that covers pipe vents and helps ensure the watertight seal around the pipe. A good pipe can hold a seal no matter the weather, but they do have a shelf life. Make sure you have an EPDM or silicone pipe boot perfectly sized to the pipe you need. Silicone is best for hot pipes. EPDM can only withstand temps up to around 212 F.

The quality of your boot installation will depend on the quality of the roofing sealant you use, so it's important to ask your supplier about the right size pipe as well as a recommendation for the perfect sealant to complement it.

Work With the Best

At Hill Country Metal Roofing Supply, we have all the metal roof accessories you need to complete your project without any delays. If you run short on any material, in most cases, we can have it to you the same day or the next. We can roll your roof panels on site so you can make last-minute changes without big delays, and we take care of all your shipping needs so you can rest easy. Contact Hill Country Metal Roofing Supply today and find out how our array of metal roof accessories and custom-rolled panels can help you get your project rolling ASAP.

Get A Free Quote Today!

Drip Metal

Roof edges get the most moisture, especially if you have an irregularly shaped or very steep roof. Drip edge flashing metal directs the water where you want it to go, like into a gutter, and extends the longevity of your roof. Your drip metal flashing should be custom-made to match the size and shapes you need so you can install it at any angle and to any measurement.

Coping

The most vulnerable part of your walls are the horizontal surfaces at the top. If water is going to make its way in, it will be through this point. A properly fitted coping with a continuous edge strip can be used alone, or in combination with other materials, to protect the walls.

To figure the size of coping you'll need, be sure to note the weight of the material you want to use, the angle of the gutter sides, and the width of the gutter bottom. Once again, getting precisely the size and shape you need is crucial to keeping a project running smoothly.

Metal Roofing Screws

To ensure a solid roof, you need the right screws, with heads that won't rust and micro-bits for quick penetration. The final choice of screw will depend on whether your substrate is concrete, metal, or wood and whether the screw needs to go through insulation. Uplight requirements should also be taken into consideration, but the two most important issues are the length and screw material.

The material will determine longevity and strength. Getting the right length of screw means the threads will properly attach to the substrate. When you consider screws, ask your supplier about the pullout loads to ensure you're getting the strength you need.

Gutters

Your roof isn't finished without gutters, but putting in guttering for metal roofs is a bit different from the way it's done on roofs made of traditional materials. In the first place, it's important to install your guttering a bit higher when joining it to a metal roof to be sure it catches the rain. It's also important to install a strong leaf guard.

In most cases, using a gutter system with brackets that attach to the fascia is your best choice. Attach the guttering through the fascia and into the rafter tails, and consider using six-inch rather than five-inch gutters for the best performance.

Underlayments

Roofing underlayments keep the roof deck dry before and throughout your roofing project. Once the roof is on, the underlayment provides a secondary line of protection against water and weather if the roof should fail at any point. Traditional roofing makes do with 30-pound felt paper underlayment, but for metal roofing, synthetic underlayments may provide superior performance because they are more tolerant of UV radiation and heat.

Synthetic underlayment can be up to 30 degrees cooler than paper while still ensuring that any water that gets past the metal roofing doesn't pass into the interior walls or any attic spaces. Look for wrinkle-free synthetic underlayment with anti-slip coatings. For some situations, paper might be the best choice, so talk to your underlayment supplier about the best underlayment for your particular project.

Custom Crickets

Wherever your roof is penetrated, you have a weak point. The joints between the roof and the chimney, or the roof and a skylight, are the most likely areas for leaking to begin. Joints must be flashed well, and you do that best with custom-made crickets that fit your project needs.

Look for a provider who can get you crickets built to any profile, size, or angle you need, so there's no delay to your project.

Chimney Caps

If your roof has a chimney, you want a custom-made chimney cap that matches the rest of your metal roof. These caps are essential for safe chimney functioning. They keep out birds, raccoons, and squirrels, protect your chimney itself from rain and leaves, and stop sparks from flying out. To top it all off, a well-made chimney cap simply looks good and adds to the aesthetic value of a roof.

Chimney caps can be made flat or peaked and made to fit any type of chimney without interfering with any convection cooling features (if your chimney is air-cooled).

Metal Trim and Flashing

Your trim and flashing are essential to keep water from getting through a joint. They are also key to your weather-resistant barrier system. The trim and flashing bring the metal panels together and, in conjunction with butyl tape, sealants, or other closures, provide a safe, watertight connection. Flashing and trim should be custom-cut to match your roofing project requirements.

Choosing Trim

The trim brings your roof together aesthetically, but it also protects and seals. You might put trim on the eaves primarily for decoration, but in other areas, the trim is far more essential. Rake trim or gable trim runs along the edge of your roof line, where the roof panel meets the end-wall panels: a key area that must be protected.

Transition trim, also known as sidewall and end-wall trim, is also important anywhere the roof meets the wall to seal any gaps in these abutting areas. Ridge caps protect the seam where two roof caps meet. Valley flashing is key anywhere the roof meets and forms a valley, to prevent water from getting under a panel.

Sealants and Caulking

Sealants and caulking are key to the life of your roof and the structure it protects. They fill in gaps and cracks and act as a barrier against anything you don't want getting through the roof, from water and dust to gas, noise, and air. Though these are some of the cheapest metal roof accessories, they are absolutely crucial to the project, and it's important to have plenty on hand.

Caulks

These are used anywhere you need sealant or filling, but where don't expect the metal in that area to expand or contract. Caulks are also used to prepare for painting. The key thing to know is that caulk is not flexible, so use it wisely. For metal roof projects, caulking usually goes on the interior gaps between drywall, around windows or trim, and on casework before painting.

Butyl Tape

This is a non-curing compound sealant that stays flexible even after exposure to the elements over time. Good butyl tape can last for 25 years or more and is compatible with all types of painted metal. Best of all, you can apply the tape at temperatures anywhere from -5 F to 120 F, and it will still provide good service at -40F and up to 200 F.

Sealants

Sealants function much like caulk but are used when you expect a lot of expansion or movement. The polymers in sealant allow it to flex, so it works well in places where two metal substrates meet, and you must have a watertight barrier. These can go on standing seams, metal roof ends, curbs, roof to wall transition points, boots, and more. Silicone sealants are popular and adhere very well, but they can't normally be painted.

Polyurethane sealant moves exceptionally well in joints and offers good adhesion for all materials except glass, though not as good as silicone. There are also butyl sealants, hybrid sealants, and many other choices, so talk with your metal roofing accessories supplier to learn more about what's right for your project.

Boots

Roof boots go into the flashing that covers pipe vents and helps ensure the watertight seal around the pipe. A good pipe can hold a seal no matter the weather, but they do have a shelf life. Make sure you have an EPDM or silicone pipe boot perfectly sized to the pipe you need. Silicone is best for hot pipes. EPDM can only withstand temps up to around 212 F.

The quality of your boot installation will depend on the quality of the roofing sealant you use, so it's important to ask your supplier about the right size pipe as well as a recommendation for the perfect sealant to complement it.

Work With the Best

At Hill Country Metal Roofing Supply, we have all the metal roof accessories you need to complete your project without any delays. If you run short on any material, in most cases, we can have it to you the same day or the next. We can roll your roof panels on site so you can make last-minute changes without big delays, and we take care of all your shipping needs so you can rest easy. Contact Hill Country Metal Roofing Supply today and find out how our array of metal roof accessories and custom-rolled panels can help you get your project rolling ASAP.

By christine

•

May 16, 2021

Choosing to install a metal roof is an excellent decision for numerous reasons, including the fact that it will last much longer than a traditional roof, is more energy-efficient, and is better for the environment. However, there are some accessories that are highly recommended for your metal roof that will help make it more effective. These nine metal roof accessories will not only greatly enhance your roof's effectiveness, but will also increase its durability as well.

By christine

•

March 8, 2021

How heavy is a metal roof? You might be surprised to learn that it is one of the lightest options. Metal roofs are lighter than asphalt shingles, clay & concrete tiles. The weight of 26-gauge metal roofing is approximately just under one pound per square foot. The weight of 24-gauge metal roofing is about 1.15 pounds. The lower the gauge of the metal, the thicker and heavier the material will be.